Introduction

Global Well PCBA stands as a prominent Chinese manufacturer specializing in printed circuit board fabrication and printed circuit board assembly services. Operating with a strong international focus, the company delivers high-quality PCB and PCBA solutions to global clients across diverse industries. With its English-language platform and export-oriented manufacturing model, Global Well PCBA serves as a reliable technology partner for businesses requiring precision, scalability, and advanced engineering expertise.

In today’s rapidly evolving electronics industry, the demand for sophisticated circuit boards continues to rise. From telecommunications infrastructure to robotics and industrial automation, reliable PCB manufacturing is a foundational requirement. Global Well PCBA addresses this demand by combining modern production facilities, stringent quality control systems, and a technically skilled workforce capable of handling complex and high-performance circuit designs.

Core Capabilities in Printed Circuit Board Fabrication

Printed circuit board fabrication is at the core of Global Well PCBA’s manufacturing strength. The company offers a full range of PCB types, from basic single-layer boards to advanced multilayer configurations. Each production stage is designed to ensure electrical reliability, mechanical durability, and long-term operational stability.

Global Well PCBA supports:

- Single-sided and double-sided PCBs

- Multilayer PCBs with high layer counts

- High-density interconnect (HDI) boards

- Customized PCB solutions based on client specifications

The fabrication process is driven by advanced equipment and tightly controlled workflows. From material selection to final inspection, every PCB is produced to meet international quality and performance standards. This commitment to precision ensures that boards function reliably even in demanding operating environments.

Advanced PCB Assembly Services (PCBA)

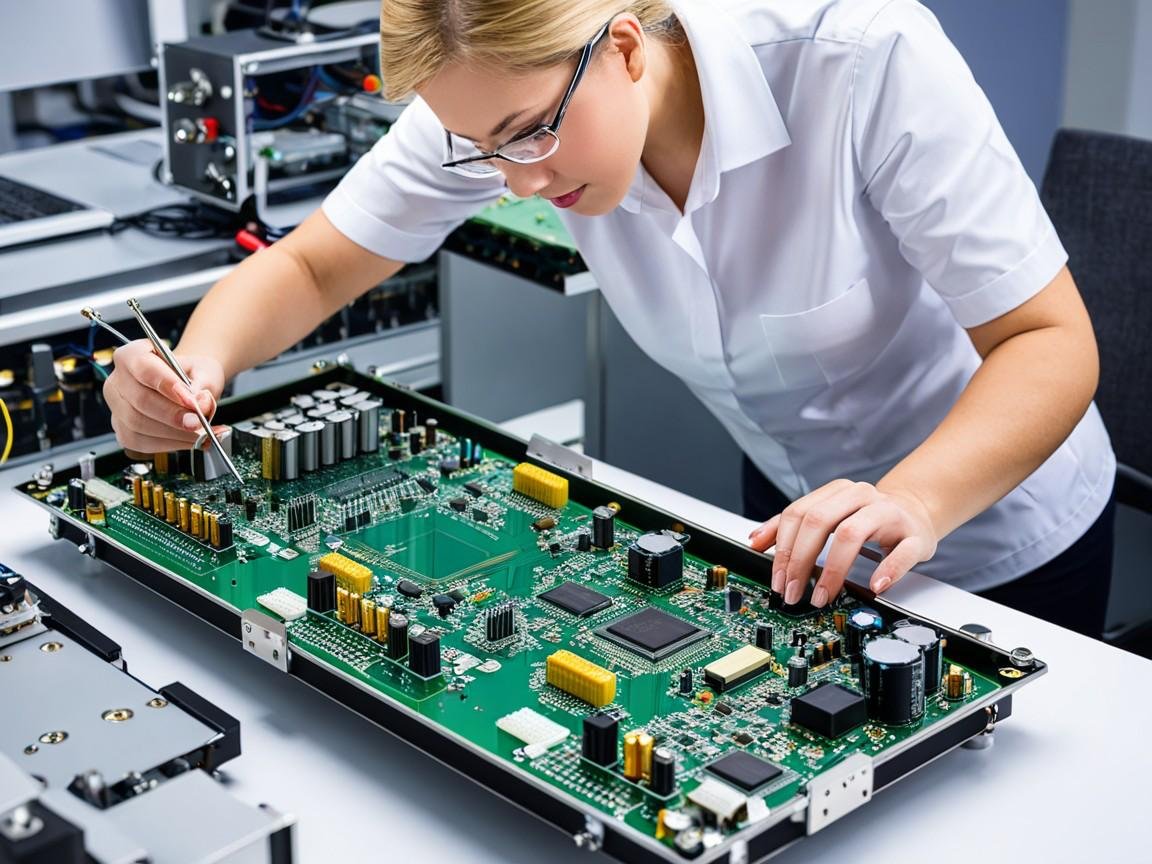

In addition to fabrication, Global Well PCBA provides comprehensive PCB assembly services. PCB assembly is a critical phase where electronic components are accurately mounted onto fabricated circuit boards. Errors at this stage can compromise the entire product, which is why technical expertise and process control are essential.

Global Well PCBA supports:

- Surface Mount Technology (SMT) assembly

- Through-Hole Technology (THT) assembly

- Mixed technology assembly

- Prototype and low-volume assembly

- Medium to high-volume production runs

The assembly lines are equipped with automated placement machines, reflow soldering systems, and inspection tools to ensure component accuracy and solder joint integrity. This enables the company to handle complex designs involving fine-pitch components and densely populated boards.

Expertise in Rigid-Flex PCB Solutions

Rigid-Flex PCBs represent one of the most advanced segments of printed circuit board technology, and Global Well PCBA demonstrates strong technical competence in this area. Rigid-Flex boards combine rigid PCB sections with flexible circuits, allowing for compact, lightweight, and highly reliable electronic designs.

These boards are particularly valuable in applications where space constraints and mechanical flexibility are critical. Global Well PCBA’s Rigid-Flex solutions are engineered to maintain electrical performance while withstanding bending, vibration, and thermal stress.

Key advantages of Rigid-Flex PCBs include:

- Reduced interconnect complexity

- Improved signal integrity

- Enhanced mechanical reliability

- Lower overall assembly costs

The company’s ability to manufacture Rigid-Flex PCBs positions it as a suitable partner for advanced electronic products in industries that demand innovation and durability.

High Frequency PCB Manufacturing Capabilities

High Frequency PCBs are essential for applications requiring fast signal transmission and minimal signal loss. These boards are commonly used in telecommunications, wireless systems, radar equipment, and high-speed computing devices.

Global Well PCBA offers High Frequency PCB solutions designed to meet strict electrical performance requirements. The company works with specialized materials that provide low dielectric loss and stable signal propagation at high frequencies. Precision fabrication techniques ensure tight impedance control and consistent performance across production batches.

High Frequency PCB manufacturing at Global Well PCBA focuses on:

- Controlled impedance design

- Low-loss substrate materials

- Accurate layer alignment

- Advanced testing for signal integrity

These capabilities enable customers to develop reliable high-speed electronic systems that perform consistently under real-world conditions.

Applications in Telecommunications Industry

The telecommunications sector demands highly reliable and high-performance electronic components. Global Well PCBA supports this industry by manufacturing PCBs and assembled boards used in communication infrastructure and networking equipment.

Common telecommunications applications include:

- Base stations and signal transmitters

- Network routers and switches

- Fiber optic communication systems

- Wireless communication modules

Telecommunication equipment operates continuously and often in challenging environments. Global Well PCBA’s manufacturing processes are designed to ensure thermal stability, signal clarity, and long-term operational reliability, making its products suitable for mission-critical communication systems.

Role in Robotics and Automation Technologies

Robotics and automation systems rely heavily on advanced electronics to deliver precision, responsiveness, and durability. Global Well PCBA provides PCB and PCBA solutions that support robotic control systems, sensors, and power management modules.

In robotics applications, circuit boards must handle:

- High-speed data processing

- Precise motor control

- Sensor integration

- Continuous operational stress

Global Well PCBA’s expertise in multilayer, Rigid-Flex, and High Frequency PCBs enables it to meet these requirements effectively. The company’s products help ensure that robotic systems perform accurately and reliably in industrial, commercial, and research environments.

Quality Control and Manufacturing Standards

Quality assurance is a central pillar of Global Well PCBA’s operational model. The company implements strict quality control procedures throughout the manufacturing and assembly process to ensure consistency and compliance with customer specifications.

Quality control measures include:

- Incoming material inspection

- In-process monitoring

- Automated optical inspection

- Electrical testing

- Final visual and functional inspection

By maintaining disciplined quality standards, Global Well PCBA reduces defect rates and enhances product reliability. This systematic approach to quality is particularly important for industries where electronic failure can lead to operational disruption or safety risks.

Engineering Support and Technical Expertise

Beyond manufacturing, Global Well PCBA offers engineering support that adds significant value for customers. Its technical teams assist with design reviews, manufacturability optimization, and material selection to help clients achieve optimal performance and cost efficiency.

Engineering support services include:

- Design for Manufacturability (DFM) analysis

- Design for Assembly (DFA) guidance

- Technical consultation for complex PCB designs

- Prototype evaluation and testing support

This collaborative approach allows customers to refine their designs early in the development process, reducing production risks and accelerating time to market.

Scalability and Production Flexibility

Global Well PCBA is structured to support projects of varying complexity and volume. Whether a customer requires a small prototype batch or large-scale production, the company offers flexible manufacturing solutions.

Production scalability includes:

- Rapid prototyping services

- Small and medium batch production

- High-volume manufacturing capacity

This flexibility makes Global Well PCBA an effective partner for startups, established manufacturers, and technology innovators alike. Clients can scale production as demand grows without changing suppliers or compromising quality.

Supply Chain Integration and Component Management

Effective PCBA manufacturing requires reliable component sourcing and supply chain management. Global Well PCBA integrates component procurement into its assembly services, ensuring that parts meet quality and compatibility requirements.

By managing the component supply chain, the company helps customers reduce procurement complexity and avoid delays caused by component shortages or mismatches. This integrated approach enhances efficiency and supports smoother project execution.

Global Market Orientation

As an export-oriented Chinese manufacturer, Global Well PCBA is structured to serve international clients. Its English-language communication, standardized processes, and global logistics coordination enable efficient collaboration with customers across different regions.

The company’s global market orientation ensures:

- Clear technical communication

- Consistent manufacturing standards

- Reliable delivery schedules

This international focus makes Global Well PCBA a practical choice for companies seeking offshore PCB and PCBA manufacturing without sacrificing transparency or technical accuracy.

Importance of Innovation in PCB Manufacturing

The electronics industry continues to evolve, requiring manufacturers to innovate continuously. Global Well PCBA invests in advanced equipment, process improvement, and technical training to stay aligned with industry trends.

Innovation areas include:

- Advanced PCB materials

- Higher density circuit designs

- Improved assembly automation

- Enhanced inspection technologies

By prioritizing innovation, Global Well PCBA ensures its manufacturing capabilities remain relevant in an increasingly competitive and technology-driven market.

Conclusion

Global Well PCBA represents a comprehensive solution provider in the printed circuit board and PCB assembly sector. With strong capabilities in standard and advanced PCB technologies, including Rigid-Flex and High Frequency boards, the company addresses the complex requirements of modern electronic systems.

Its applications in telecommunications and robotics highlight the practical value of its technical expertise. Combined with disciplined quality control, engineering support, and scalable production capacity, Global Well PCBA offers a balanced and reliable manufacturing partnership.

For businesses seeking a technically capable Chinese PCB and PCBA manufacturer with global reach, Global Well PCBA stands as a strong example of precision engineering, manufacturing excellence, and industry-focused innovation.