Key Takeaways

- Understand the different types of electrical conduits and their applications.

- Consider environmental factors and local codes when selecting a conduit to ensure compliance with regulations.

- Proper installation and maintenance are crucial for the longevity of conduit.

Selecting the right electrical conduit is a crucial step in planning any electrical installation. The conduit not only safeguards your wiring from physical damage but also ensures compliance with safety codes. Making the wrong decision can lead to costly repairs and increase the risk of electrical hazards over time. If you’re beginning your next project and want more details about conduit types or prices, click here for further information.

Your choice will be influenced by where the conduit is installed, its exposure to harsh conditions, and the long-term durability requirements. The National Electrical Code outlines specific requirements depending on your environment. Whether you’re working on a home renovation or a large industrial project, careful conduit selection ensures your system runs reliably for years to come.

Understanding how these conduits differ can help you prevent downtime, keep costs under control, and facilitate easier maintenance in the future. By following professional best practices and local regulations, you reduce the risk of future electrical issues.

The right conduit protects against moisture, chemicals, and impact, but it also must be the correct size for your wiring needs. Factors such as conduit material and flexibility will matter most when planning your installation. Always rely on trusted suppliers or electrical experts if you’re unsure which product to choose. For a breakdown of conduit types, compliant installation, and upkeep, keep reading this comprehensive guide.

Types of Electrical Conduits

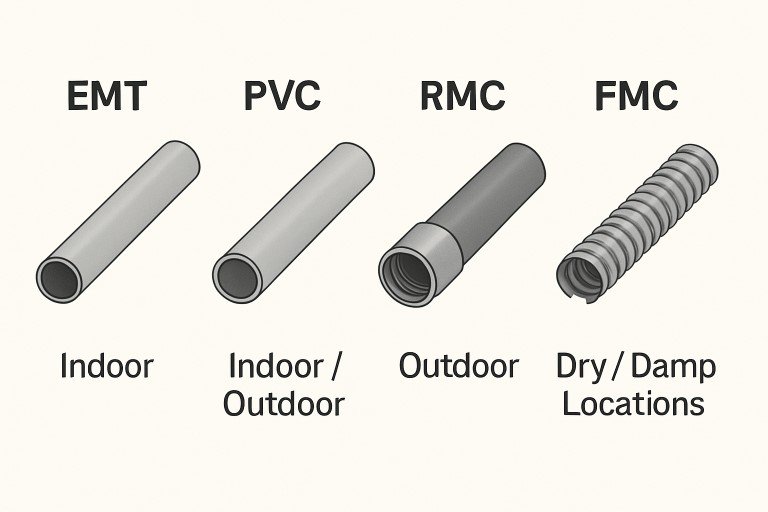

Electrical conduits serve as the backbone for robust electrical installations, offering protection and meeting code requirements. Each material is specifically designed to tackle different situations and risks:

- Electrical Metallic Tubing (EMT): Also known as “thin-wall,” EMT is favored for indoor installations in both commercial and residential applications. Its lightweight design makes it easy to cut and fit, but it should not be used in areas where heavy physical impacts or outdoor exposure are likely.

- PVC Conduit: Popular for underground and outdoor applications, this plastic conduit is non-conductive, resistant to corrosion, and easy to work with. However, it can become brittle over time in high-impact or high-UV settings.

- Rigid Metal Conduit (RMC): This heavyweight, thick-walled option delivers maximum strength, making it ideal for harsh or high-risk locations. It can also be threaded and coupled for secure, long-lasting installations.

- Flexible Metal Conduit (FMC): Designed to snake through tight or irregular spaces, FMC offers ease of routing but is best kept to dry, low-impact indoor environments.

- Liquid-tight Flexible Metal Conduit (LFMC): With a durable, waterproof layer, LFMC performs well in wet or corrosive conditions, such as outdoor air conditioning units or exposed industrial workspaces.

For additional insight into conduit materials and regulations, consider referencing GlobalSpec’s Electrical Conduit Selection Guide.

Factors to Consider When Choosing a Conduit

Your installation site and project specifics will significantly dictate the type of conduit to be selected. Environmental concerns, like moisture, temperature, and impact, should be top of mind. For example, PVC or coated flexible metal conduits are preferred in corrosive areas, such as farms or factories with chemical exposure.

- Environmental Conditions: Water, chemicals, temperature swings, and even pests can challenge the integrity of specific conduits. Outdoor and underground applications require materials that resist long-term deterioration.

- Compliance with Codes: Every region and building project must meet both local building codes and the National Electrical Code (NEC). This ensures the system is safe, legal, and insurable. The NEC provides minimum depth and material standards to reduce fire and shock risk. For the most recent NEC updates, visit the National Fire Protection Association’s NEC page.

- Size and Capacity: Never overfill a conduit. Evaluate the number of wires that will run and their corresponding sizes. NEC Chapter 9, Table 1 offers fill capacities and guidelines for each conduit type.

- Durability and Longevity: Materials like galvanized steel can resist corrosion and physical wear better than plastic alternatives, making them preferable for high-traffic or exposed locations.

Installation Best Practices

Plan and Design

Start with a thorough site survey and sketch a plan that outlines all conduit runs and junction box locations. Pre-planning detects potential conflicts with other systems, such as water pipes or HVAC ductwork, helping you avoid unnecessary damage during installation.

Choose the Correct Conduit Size

Sizing is not just about convenience—it’s crucial for code compliance and safety. Reference NEC Chapter 9 to make calculations, and always allow some space for future wiring expansion.

Minimize Bends and Directional Changes

Excessive bends complicate wire pulls and routine maintenance. National code limits the total bends between pull points to 360°. If possible, keep bends to a minimum, aiming for no more than three to reduce friction and simplify repairs.

Quality and Secure Mounting

Don’t cut corners when purchasing conduit and fittings. Inexpensive materials may save money upfront, but they can cause premature wear or even lead to code violations. Secure conduits with appropriate supports and clamps, especially for runs longer than 1.5 meters, and use only fittings matched to the conduit type.

Maintenance and Inspection

Regular Checks for Wear

Periodic inspections catch minor issues before they escalate into larger problems. Watch for warping, corrosion, broken clamps, or cracked conduit. For large installations, thermal scanning can identify overheating caused by poor wire contact or degraded insulation.

Repair and Documentation

Promptly replace or repair damaged sections of conduit. Keep a log of all inspections, repairs, and upgrades, which assists with future troubleshooting and satisfies most regulatory requirements. Maintenance data can also be helpful should you ever need to expand or revise your conduit system.

Conclusion

Properly selected and installed electrical conduit forms a reliable, safe backbone for your electrical system. It prevents hazards, eases maintenance, and ensures your installation remains compliant with codes and regulations. Always match your conduit choice to the installation environment, follow professional standards, and inspect your system regularly to maintain optimal performance over the years.