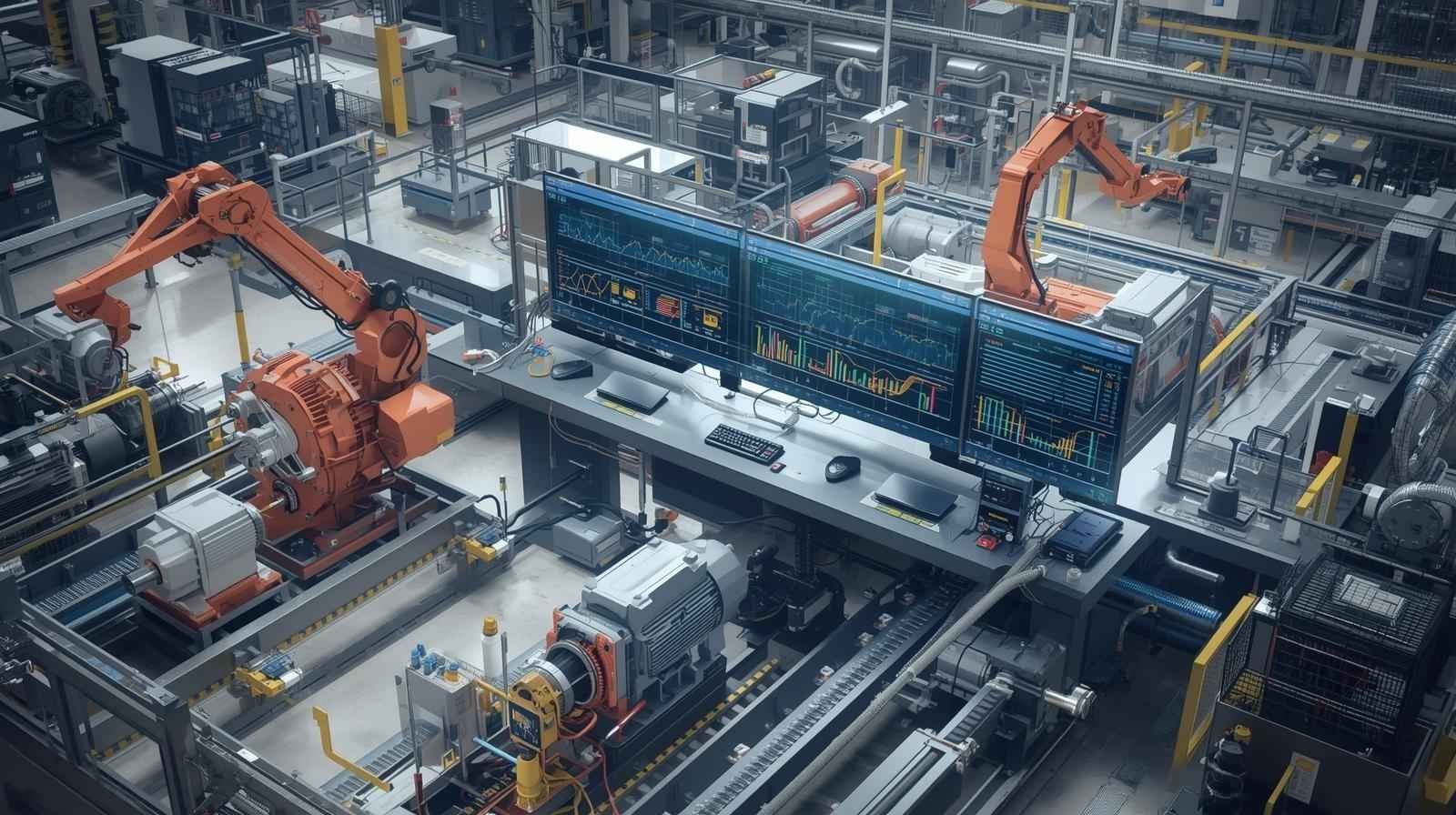

The modern factory floor is a symphony of moving parts. Motors whir, conveyors shift, and sensors constantly measure temperature, pressure, and flow. But without a conductor to interpret these signals and guide the instruments, the result would be chaotic noise rather than a synchronized production line.

This is where Supervisory Control and Data Acquisition (SCADA) enters the picture. It acts as the central nervous system for facilities ranging from water treatment plants to automotive assembly lines. By aggregating data from scattered sensors and presenting it in a human-readable format, SCADA allows operators to make split-second decisions that keep operations running smoothly.

Understanding how these systems function—and more importantly, how they are integrated—is essential for any organization looking to modernize its infrastructure. This guide explores the mechanics of SCADA Industrial Automation, the vital role of programming, and why seamless integration is the key to unlocking true operational efficiency.

The Architecture of Control

To grasp the power of a SCADA system, you have to look past the screens in the control room and understand the hierarchy of hardware and software working in the background. It is not a single device, but a layered architecture designed to bridge the gap between physical machinery and digital decision-making.

The Field Level

At the ground level, you have the “eyes and hands” of the operation. This includes sensors and actuators that interact directly with the machinery. They might detect the level of liquid in a tank or the speed of a turbine. These devices are connected to Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs).

The Communication Layer

PLCs and RTUs are robust computers built for harsh environments. They take the raw electrical signals from the sensors and convert them into digital data. However, this data is useless if it stays trapped in the machine. A communication network—often a mix of Ethernet, serial connections, or wireless protocols—transmits this information up the chain.

The Supervisory Station

This is the heart of SCADA Industrial Automation. The supervisory computer gathers data from all the PLCs and RTUs. Unlike the local controllers, which focus on specific machines, the supervisory station looks at the big picture. It processes the incoming stream of information, logs historical data, and triggers alarms if parameters drift outside of safe limits.

The Role of SCADA Programming

Hardware is only half the equation. For a system to truly serve the needs of a facility, it requires precise configuration. SCADA programming is the process of defining how the software interprets data and how it reacts to specific conditions.

This involves mapping thousands of data points (tags) to visual elements on a screen. A programmer must define what happens when a tank reaches 90% capacity. Should a light turn red? Should an audible alarm sound? Should a valve automatically close?

Effective SCADA programming transforms raw binary code into intuitive graphics. It allows an operator to look at a screen and instantly understand the status of a complex process through color-coded pipes, animated fans, and trending graphs. If the programming is poorly executed, the operator may be overwhelmed with nuisance alarms or confusing interfaces. If done well, it simplifies complexity and empowers the workforce to act proactively.

Why System Integration Matters

Buying a SCADA software package and a few PLCs is not enough to guarantee efficiency. The real challenge—and the real value—lies in system integration.

Many industrial facilities operate with a “patchwork quilt” of legacy equipment. You might have a stamping press from the 1990s using one communication protocol, a packaging robot from 2010 using another, and a brand-new HVAC system using a third. These disparate systems often speak different languages.

Breaking Down Silos

System integration is the art of unifying these isolated silos into a single, cohesive ecosystem. A robust SCADA Industrial Automation strategy focuses on interoperability. It utilizes gateways and drivers to translate different protocols (like Modbus, MQTT, or OPC UA) so that every machine can communicate with the central system.

When systems are properly integrated, data flows freely across the enterprise. The production manager can see inventory levels in real-time, the maintenance team can monitor motor vibration trends to predict failures, and the quality control department can trace product batches back to specific processing conditions.

Benefits of a Modern SCADA Approach

Investing in high-quality system integration and SCADA technology yields returns that go beyond simple monitoring.

Real-Time Visibility

The primary advantage is situational awareness. Operators no longer need to walk the plant floor with a clipboard to check gauges. They have a bird’s-eye view of the entire facility from a central location. This immediate access to data reduces response times significantly. If a machine jams, the system identifies the exact location and nature of the fault instantly.

Historical Analysis and Optimization

SCADA systems function as historians. They store vast amounts of data over time, allowing managers to analyze trends. By reviewing historical performance, engineers can identify bottlenecks in the production line or spot inefficiencies in energy usage. This data-driven approach moves maintenance from a reactive “fix it when it breaks” model to a predictive model.

Scalability and Flexibility

Modern SCADA architectures are designed to grow. As a business expands, new production lines or remote sites can be added to the existing network without tearing down the infrastructure. Cloud-based integration allows for even greater flexibility, enabling authorized personnel to access system data securely from mobile devices or off-site locations.

The Future of Industrial Control

The line between traditional automation and Information Technology (IT) is blurring. We are entering an era often referred to as Industry 4.0, where SCADA Industrial Automation is merging with the Industrial Internet of Things (IIoT).

In this new landscape, SCADA systems are not just monitoring loops; they are gateways to the cloud. They are feeding data into Artificial Intelligence algorithms that can optimize production schedules in real-time. Integration services are becoming more sophisticated, prioritizing cybersecurity and edge computing to handle the massive influx of data generated by smart sensors.

Despite these technological leaps, the core purpose remains the same: control and acquisition. The goal is to give human operators the tools they need to manage complex physical processes safely and efficiently.

Empower Your Operations with Integration

A SCADA system is more than software installed on a computer; it is a strategic asset that dictates the pulse of your production. Whether you are upgrading a legacy system or building a new facility from the ground up, the success of the project hinges on professional integration and thoughtful SCADA programming.

By bridging the gap between hardware and software, and ensuring all components of your facility speak the same language, you create an environment where data drives decision-making. Don’t let your valuable operational data disappear into a black hole. Harness it to drive efficiency, reduce downtime, and secure the future of your industrial operations.